Customization, quality, and care.

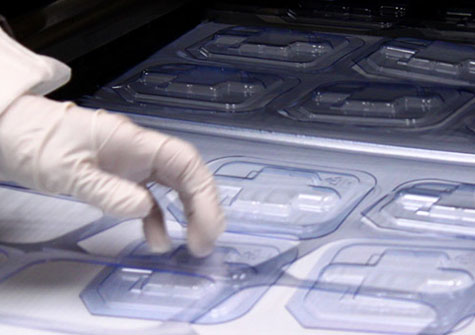

Janco is proud to be your trusted partner for cost-effective, high-quality thermoformed plastic products.

Our team offers both thin gauge and thick gauge thermoforming, utilizing our extensive capabilities to bring your products to life, ranging from single-use medical packaging to durable, reusable industrial process trays.

We routinely thermoform plastic and foam materials in a variety of colors, densities, and thicknesses.

Details

Our engineers can assist you with any part of the process where you need some guidance, including material selection for desired properties such as:

- Biocompatibility

- Anti-static

- Fire-retardancy

- Impact

- Abrasion resistance

- And more

If you need it, we can engineer it.

Janco delivers thermoforming services for several markets, from consumer to the electronic industries. Our team of experienced engineers will develop a solution for virtually any product you need, including:

- Blister packaging

- Covers

- Clamshells

- Automation trays

- Enclosure

- Inserts

- Protective cases

- Protective cases

- Industrial process trays

- Automotive component packaging

- Electronics packaging

Janco has strategically positioned ourselves as a distributor of high-performance plastic and foams. That means you benefit from working with a partner that has a distinct advantage when it comes to sourcing, supplying, and meeting your high-volume, mid-volume, or low-volume needs, with competitive pricing at every level.

We work with a wide range of materials, including:

- PET, PETG, PETE (polyethylene terephthalate)

- HIPS (high impact polystyrene)

- Acrylic

- PVC (polyvinyl chloride)

- Kydex®, a trademarked acrylic/PVC alloy

- ABS (acrylonitrile butadiene styrene)

- PC (polycarbonate)

- PP (polypropylene)

- PS (polystyrene)

- HDPE (high-density polyethylene)

- TPU (thermoplastic polyurethanes)

- TPO Foams (thermoplastic olefins)

- And others, depending on your application

Janco’s Core Thermoforming Capabilities

- Bed size: 29″x 32″ gauge range of .007″ to .060″

- Thermoforming and Fabrication Cleanrooms certified to ISO 14644-1 Class 8

- Fully-automated inline thermoforming machines

Heavy Gauge Pressure-Thermoforming

- Bed size 48″ x 72″, Gauge range of .006″ to .500″ with 24″ depth of draw

- In-house design assistance, prototype, REN, and production tooling

- ISO 13485 Certification, FDA Registered

- Thermoforming and Fabrication Cleanrooms certified to ISO 14644-1 Class 8